PLC model: intelligent high-precision high-energy magnetic polishing machine

Application field: Suitable for complex parts with deep holes, stainless steel, iron, copper, zinc, aluminum, magnesium alloys between walls, titanium hard plastics, and other materials through stamping, die-casting, casting, forging, automatic stretching lathes, powder metallurgy, CNC machining centers and other processes

Classification:

Intelligent high-energy magnetic series

Key words:

PLC model: intelligent high-precision high-energy magnetic polishing machine

Contact Us

Product Description

Specification parameters

Input power supply: three-phase 380VAC (50/60HZ) 15A

Mechanical size: L1100Xw740xH1320mm

Working slot size: L720 * W530mm

Maximum processing capacity: 560 * 420mm

Processing speed: 0-60HZ (1-2)

Operation mode: ↑◐◑↓

Machine weight: 300kg

Principle:

The power of driving a high-energy magnetic field guides the medium abrasive stainless steel magnetic needle to flow on the surface of the workpiece in multiple directions, quickly, and with rotational jumping, achieving efficient deburring, polishing, decontamination, cleaning, and other grinding and polishing effects.

Unique advantages:

1. Precision control of grinding parameters, capable of handling large cavity components of 550 * 450 * 80mm

2. Original intelligent processing mode: split single side processing mode; Two types of front/back machining modes

3. The product has a prompt function on the flip side, and the automatic management function for grinding fluid life. The liquid change prompt function allows for controllable grinding fluid life

4. System automatic diagnosis of errors, abnormal operation alarms, and other functions

5. Intelligent control can minimize the negative effects caused by human factors, and humans can simply perform actions like machines

6. Machine wet grinding, no dust generated during the process, reducing workshop dust by more than 50% without affecting the environment.

Application field:

Widely used in fields such as aerospace, medical equipment, military industry, precision machinery, instrumentation, communication, automobiles, optoelectronics, electronics, microelectronics, computers, jewelry, watches, high-end household goods, etc;

For large and complex components with deep holes, stainless steel, iron, copper, zinc, aluminum, magnesium alloys, titanium hard plastics between walls, and other materials, through stamping, die-casting, casting, forging, automatic stretching lathe, powder metallurgy, CNC machining center and other processes, workpiece surface polishing, deburring, rust removal treatment, sintering marks, and removal of oxide film.

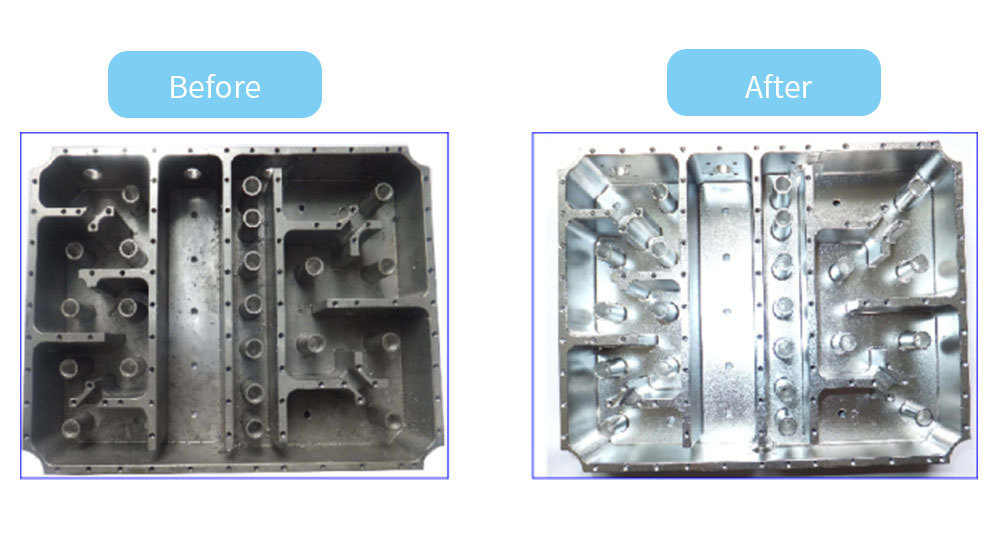

Comparison diagram of cavity components before and after grinding:

Professional solutions for your industry, ready for your choice

Related Products